General

This module is a core requirement for the Advanced Product Design Engineering students but may be of interest to students on other master courses who have the required background and are looking for an option that will broaden their knowledge of this subject area. The module is structured in a way to develop an in-depth understanding of some of the fundamental CAD/CAM/CAE computing technologies that support the engineering product development process. The module also develops both an understanding of the role of these technologies within Product Data Management (PDM) systems and the role of PDM itself as one of the key enablers for Product Lifecycle Management (PLM).

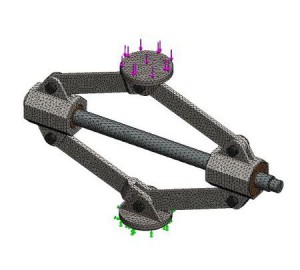

The module is structured so that around 50% of the teaching and learning time is focussed on practical CAD/CAE workshops and activities. This will enable students to acquire a set of skills to enhance their employability prospect in this demanding area. Core factual materials are provided via StudySpace with keynote lectures used to explain concepts of the integration of CAD/CAE systems.

Aims

- To develop a fundamental understanding of 3D Solid Modelling within the context of Computer-Aided Design (CAD).

- To develop an understanding of current and future supporting technologies for design and analysis within the engineering design process.

- To enable students to gain practical and theoretical knowledge of the analytical tools that extend the functionality of CAD.

- To utilise CAE techniques to solve a range of engineering design problems and apply appropriate kinematics and dynamics mechanism design techniques for a wide range of products.

Learning Outcomes

On successful completion of the module, students will be able to:

- Evaluate stresses and deflections in engineering structures under various complex loading conditions and determine stiffness matrices and load vectors for iso-parametric problems.

- Analyse and provide solutions for problems concerning plastic deformation, plastic flow and collapse.

- Use finite element packages in the solution of time dependent problems such as creep and non-linear problems such as buckling and large deflections.

- Demonstrate knowledge of characteristics of advanced engineering materials and identify the interrelationship between their structure and properties.

- Clarify and Evaluate how structure and properties of an advance material affect the manufacturing process

- Demonstrate how quality assurance techniques can be applied to the manufacturing processes of modern materials, and select an appropriate process to manufacture a product for a given critical application.