General

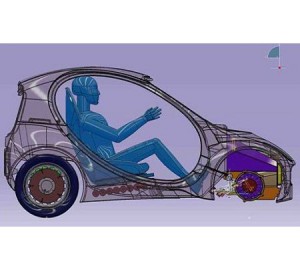

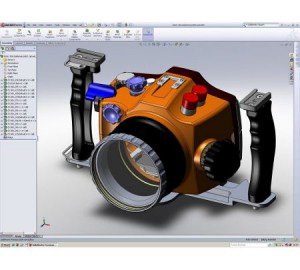

This module is a core requirement for the students on Advanced Product Design Engineering and Advanced Industrial Manufacturing Systems students but may be of interest to students on other master courses who have the required background and are looking for an option that will broaden their knowledge of this subject area. The module covers advanced CAD/CAM/CNC techniques in the conceptual design and manufacture and is heavily focussed on the surface modelling and reverse engineering methods prior to manufacture. Reverse Engineering as well as Additive manufacturing methods involving mould design, machining tool path optimisation & full machining simulation verification, and machining collision avoidance subjects will also be covered.

The module is structured so that around 50% of the teaching and learning time is focussed on practical CAD/CAM workshops and activities. This will enable students to acquire a set of skills to enhance their employability prospect in this demanding area. Core factual materials are provided via StudySpace with keynote lectures used to explain concepts of the integration of CAD/CAM systems.

- To develop a deep knowledge and understanding of the key concept functions and applications of CAD/CAM systems in design and manufacturing process.

- To provide intensive conceptual design and manufacture hands-on training on leading industrial CAD/CAM package up to the the computer numerical control (CNC) machine data preparation and simulation.

- To enable students to develop the knowledge of the whole concept from 3D Solid geometry modelling using Reverse engineering methods to 3D Printing.

On successful completion of the module, students will be able to:

- Demonstrate a good knowledge in Reverse Engineering methodology, select and apply appropriate freeform surfaces modelling techniques from cloud data points.

- Demonstrate a good knowledge of Additive Manufacturing (3D-Printing) and its application in tooling design and validation

- Critically analyse and optimise the machining operations simulation using industrial CAD/CAM package

- Demonstrate a good understand metal removal methods of complex freeform surfaces using multi-axis computer numerical control part programming and post-processing.

- Develop an extensive knowledge in identifying the capabilities of the virtual multi-axis machining simulation and verification